Green wall

Comparison of competing green wall systems

Because each wall technique is specific, the technical elements to take into account are different. The support structure elements, the type of substrate used, the weight of the system, the consumption of water and fertilizer, the modularity, the durability of the system vary depending on the techniques.

Green wall VERTIFLORE system

The Vertiflore® green wall system is a patented product, under TECHNICAL NOTICE: n ° 2.2 / 15-1693-V1 from CSTB. The only manufacturer to have obtained a technical opinion on the added green cladding.

Trays

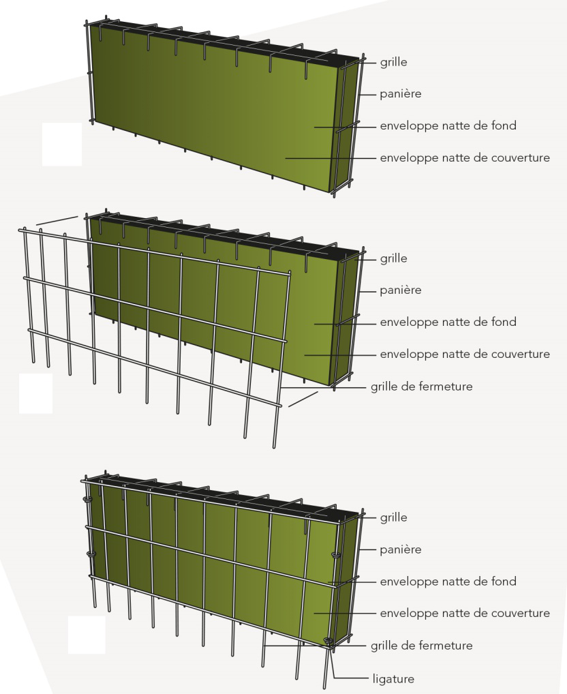

These are wire mesh cages (made of 4.8 mm GRAPAL type wires from ARCELOR with an overall dimension of: 1 m long, 37 cm high and 12 cm deep as standard). The Vertiflore® system allows each bin to be dismantled individually, anywhere on the wall surface.

As part of a possible check of the rear part of the system, it will be easy to check an attachment point or observe the condition of the insulation or load-bearing wall.

The bins are fixed to the rail by hooks adjoining the bin with slits on the back of the bin which are directly blocked in the lower bin.

For the container at the foot of the wall, the waits are blocked by a flat fixed to the lower rail, the latter rail must have an anti-tilt role.

The tubs are covered with a rot-proof moisturizing mat made from thermo-bonded black plastic fibers. The film has class M1 fire resistance. The film has a high tear capacity.

• 20 Dn lengthwise

• 12 Dn in the direction of the width

The culture medium

This substrate, studied with CRNS and INRA, allows the plant to take root properly, to create real bacterial life with microbial exchanges. Each plant benefits from 5 liters of soil. The addition of fertilizer is not necessary. No sphagnum moss, peat, or expanded polystyrene. This substrate is water-saving: from 0.3l to 2.5l / m² / day.

The culture support consists of 55% of mineral having a density of less than 0.8.

The mineral part is reinforced up to 8% of a hydro-retention agent of the palygortisk type and to 37% of bacterial leaven and retard fertilizer in organic form.

Omegas for a wall with thermal insulation of the walls from the outside

The omegas are placed vertically on the consoles. The fixing is made by a system of bolts and nuts. The omega has a minimum thickness of 2.5 mm in type S 220 GD galvanized steel receiving a magnelis 310 anti-corrosion treatment.

Classic wall rails

They are made of type S 235, galvanized steel, 2.5 mm thick in a G shape. Their role is to support the bins. They are about 2.5 m long with 2 fixing points on the load-bearing wall.

The rails are placed on the wall with a suitable system, either by anchor bolts or fixed to omegas by screws and bolts with a minimum diameter of 8 mm for walls with ite. An air space of at least 6 cm between the load-bearing wall and the green wall is necessary.

Consoles for a wall with thermal insulation of the walls from the outside

Consoles are made of hot-dip galvanized steel composed of a flat 10 to 12 mm thick and a 250 * 250 square shape on which a 120/60/5 tube is welded.

This tube is pierced to take back the omegas. The spaces between 2 consoles on the height, are 2.4 m and 1.25 on the width.

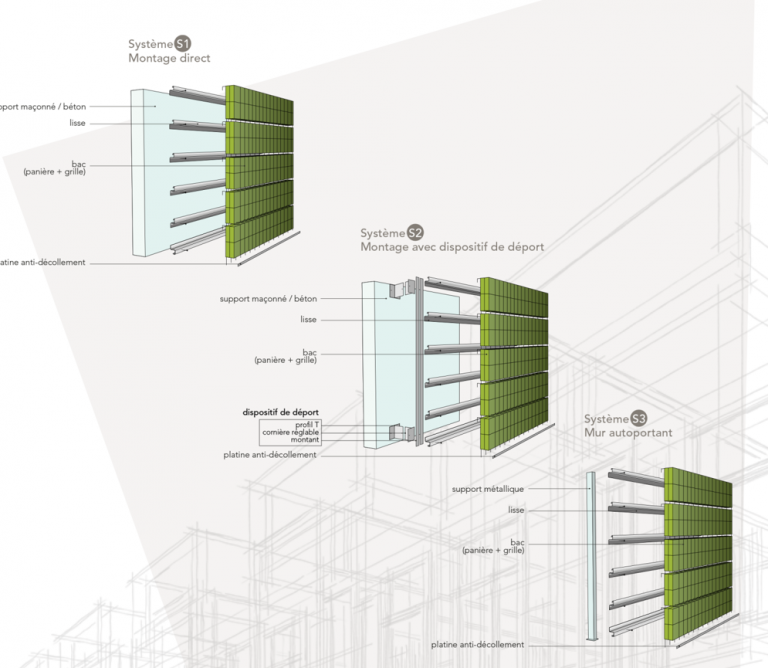

Fixing systems

3 fixing systems

On self-supporting wall

On load-bearing wall

On self-supporting wall with ETI

Automatic watering

The VERTIFLORE® watering system has the densest dripper network: a dripper line every 40 cm on the height and every 15 cm on the horizontal line, which makes it possible to optimize watering times as accurately as possible. , to give the plant just what it needs. Watering times are on average 8 minutes per day in summer and 5 minutes per week in winter.

Watering is managed by a programmer which controls the opening and closing of the solenoid valves. The solenoid valves are positioned in a technical room.

The green wall is connected through remote management of the sprinkler system with the PRO HC system from HUNTER.

This solution provides daily feedback as well as any alert on the sprinkler system. This connected system allows our maintenance department to act quickly.

Plants

The planting plan is established according to different criteria: the aesthetics of the wall (color, geometry, green all year round …), the exposure of the wall (north, south, east, west) the climate, the frequency of maintenance, choice of biodiversity.

We work on a database of more than 300 plants. The average planting density will be 25 units per m² to ensure rapid coverage of the wall.

What are the effects of vegetation on health?

A US study, involving 175 office workers, found that natural light and the view of a green space explained 6.5% of the variations in sick leave between different offices on campus.

Elzeyadi(2011), quantifying the impacts od daylight on occuppants helath

In a survey of 3,600 office workers from 8 countries, including France, respondents working in an environment with natural elements, such as plants, reported a 13% higher level of well-being and a level of 8% higher productivity compared to workers without this working environment.

Cooper(2016) rapport human spaces

A study in people hospitalized after surgery.

She has shown that patients in a room with a view of a green space need less painkillers and go out on average a day earlier than patients with a window facing a brick wall.

Greening contributes to air purification

The vegetation of cities helps trap certain gaseous pollutants in the air using two mechanisms:

- Capture by leaf stomata (mercury, arsenic, SO2, CO …)

- Storage (deposition) in leaf cuticle waxes (VOC, PAH)

A mature tree can trap up to 20kg / year of particles.

A green wall in canyon streets would reduce the concentration of pollutants in the street air, up to 40% for nitrogen oxides and 60% for PM10.

Pugh, mackenzie, whyatt jd, hewitt (2012): Effectiveness of green infrastructure for improvement of air quality inn urban street canyon